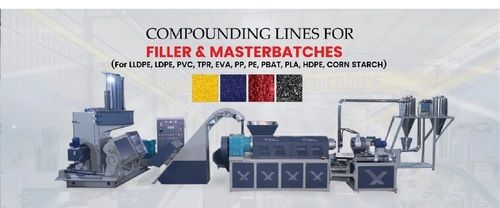

Compounding Lines For Filler And Masterbatches

Product Details:

- Product Type Compounding Lines For Filler And Masterbatches

- Material stainless steel

- Type Other

- Capacity 1200 Kg/hr

- Weight (kg) 1 Tonne

- Computerized Yes

- Automatic Yes

- Click to View more

Compounding Lines For Filler And Masterbatches Price And Quantity

- 2 Unit

Compounding Lines For Filler And Masterbatches Product Specifications

- Yes

- 1 Tonne

- 1200 Kg/hr

- yes

- stainless steel

- Compounding Lines For Filler And Masterbatches

- Other

- Yes

Compounding Lines For Filler And Masterbatches Trade Information

- Cash in Advance (CID)

- 5 Unit Per Year

- 4-5 Months

- All India

Product Description

Introducing our Compounding Lines For Filler And Masterbatches - the ultimate solution for your compounding needs. With a computerized system and automatic operation, this compounding line can process up to 1200 kg/hr, making production faster and more efficient. Made with high-quality stainless steel material, this compounding line is durable and reliable, ensuring a long-lasting service life. At one tonne in weight, it is also easy to transport and install. Plus, with a warranty included, you can rest assured that you are getting a top-quality product that will meet all your compounding needs.

A leading producer and provider of cutting-edge compounding lines for a variety of industries is Xtreme Machines. Our machines are built to provide exceptional performance, dependability, and efficiency, enabling companies to increase output while minimising downtime. Xtreme Machines offers the appropriate technology for you, whether you're searching for dedicated equipment for bio-based polymers or PVC compounding solutions.

The PVC Compounding Line, one of our best-selling items, is designed to withstand the most rigorous production settings. PVC materials are precisely mixed and compounded by our PVC Compounding Line, guaranteeing constant quality and performance. For producing a variety of PVC goods, such as cables, pipes, and profiles, our PVC Compounding Line is perfect. For manufacturers wishing to expand, the PVC Compounding Line's sophisticated features, such as automatic temperature control and high-torque mixing, provide efficiency and simplicity of use. Leaders in the industry rely on Xtreme Machines' PVC Compounding Line because of its sturdy construction and capacity for large production volumes.

Xtreme Machines is a well-known Corn Starch Compounding Line Manufacturer in addition to PVC compounding. Machines made especially to turn starch-based compounds into biodegradable products are produced by our Corn Starch Compounding Line Manufacturers. Being one of the leading manufacturers of maize starch compounding lines, we make sure that our equipment can produce high-performance results while also being ecologically friendly. Disposable goods, packaging materials, and biodegradable plastics are all produced using these devices. As manufacturers of maize starch compounding lines, we prioritise sustainability and innovation by offering products that assist companies in lowering their carbon impact.

Bio Polymer Filler Compounding Machines, which are necessary for creating environmentally friendly plastic products, are another area in which Xtreme Machines excels. PLA, PBAT, and other bio-based resins are among the biodegradable materials that our Bio Polymer Filler Compounding Machine is made to operate with. The Bio Polymer Filler Compounding Machine gives companies a competitive edge in the expanding market for biodegradable plastics by integrating the newest technologies to assure perfect compounding. Manufacturers can meet environmental standards and produce high-quality products with an Xtreme Machines Bio Polymer Filler Compounding Machine. Businesses who value sustainability and wish to provide their clients with eco-friendly solutions will find the Bio Polymer Filler Compounding Machine ideal.

The cutting-edge EVA Filler Compounding Line is offered by Xtreme Machines to companies that deal with EVA materials. The purpose of this EVA Filler Compounding Line is to compound ethylene vinyl acetate (EVA) resins, which are frequently found in adhesives, foam products and shoe soles. Xtreme Machines' EVA Filler Compounding Line ensures that your final goods exceed the highest quality standards by providing exceptional dispersion and uniformity. The EVA Filler Compounding Line's sophisticated control systems and energy-efficient operation enable firms to maximise production efficiency and save waste. For companies looking for dependable and effective compounding solutions for EVA materials, the EVA Filler Compounding Line is the ideal option.

The TPR Filler Compounding Line is another state-of-the-art product from Xtreme Machines that is intended for the processing of thermoplastic rubber (TPR) components. High-quality TPR compounds for a range of applications are produced by the TPR Filler Compounding Line, which guarantees ideal filler and additive mixing and dispersion. The TPR Filler Compounding Line is perfect for the production of flexible tubing, automobile parts and footwear. Manufacturers can produce finished goods with more flexibility, durability, and performance by using the TPR Filler Compounding Line. The TPR Filler Compounding Line from Xtreme Machines is a popular option for companies wishing to increase their production capacity because of its user-friendly design and efficiency.

Xtreme Machines provides TPR as well as the cutting-edge PE Filler Compounding Line, which is made especially for polyethylene (PE) materials. For use in consumer goods, construction, and packaging, the PE Filler Compounding Line guarantees accurate mixing and compounding, providing a constant quality. Businesses with high demands can benefit greatly from the PE Filler Compounding Line's energy efficiency and capacity to manage huge production volumes. Manufacturers may lower operating expenses and produce high-quality products with the PE Filler Compounding Line. For businesses looking for dependable and effective compounding solutions, the PE Filler Compounding Line is a great option.

ZHFR Cable Filler Machines, made for zero halogen flame retardant (ZHFR) cable applications, are another area of expertise for Xtreme Machines. The ZHFR Cable Filler Machine guarantees that the compounding procedure satisfies the strict environmental and safety standards needed for cables that are flame retardant. The ZHFR Cable Filler Machine provides excellent flame resistance and durability by providing exact control over the compounding process. Manufacturers may create premium ZHFR cables that are safe and eco-friendly using the ZHFR Cable Filler Machine. For companies in the cable production sector, the ZHFR Cable Filler Machine is a vital instrument.

Another product in our line is the Zero Halogen Cable Filler Machine, which is made especially to create zero halogen cables that are safer to use in high-risk situations. The Zero Halogen Cable Filler Machine ensures that the finished product is safe and environmentally friendly by effectively mixing components that remove dangerous halogens. Applications where safety is a top concern, such as construction, telecommunications, and transportation, are perfect for the Zero Halogen Cable Filler Machine. Xtreme Machines' Zero Halogen Cable Filler Machine is designed to meet strict safety regulations while producing high-performance results.

Xtreme Machines provides the PBAT Filler Machine to businesses that produce biodegradable plastic. Polybutylene adipate terephthalate (PBAT), a biodegradable polymer with a variety of environmentally benign uses, is processed using the PBAT Filler Machine. The PBAT Filler Machine produces high-quality biodegradable goods by guaranteeing accurate compounding. Manufacturers may create goods that satisfy environmental regulations while preserving functionality and longevity with the PBAT Filler Machine. For companies wishing to enter the green plastics market, the PBAT Filler Machine is a great option.

Last but not least, Xtreme Machines offers the cutting-edge PLA Filler Machine, ideal for compounding polylactic acid (PLA) materials. The PLA Filler Machine is a popular tool for producing biodegradable polymers, providing producers with an environmentally friendly way to meet their compounding requirements. High-quality final products are produced by precisely compounding PLA materials, which is ensured by the PLA Filler Machine. An important tool for businesses concerned with sustainability and environmentally friendly production is the PLA Filler Machine from Xtreme Machines.

Xtreme Machines is dedicated to offering compounding solutions that are of the highest calibre, inventive, and effective. Whether you require a PVC Compounding Line, EVA Filler Compounding Line, or Bio Polymer Filler Compounding Machine, Xtreme Machines has the technology and expertise to suit your manufacturing demands.

|

Model |

Kneader capacity |

Screw dia. |

L/D ratio |

Main motor |

Taper twin screw motor |

Dia face cutter |

Temperature control |

Total HP |

Space required (mtr) |

Production Kg/ Hr |

|

XMPL - 25 |

5 Ltrs |

45 mm |

20/1 |

5 HP |

3 HP AC Variable |

Air cutter |

4 point PID |

20 HP |

1.5x3.0 |

25 - 50 |

|

XMPL - 70 |

15 Ltrs |

60 mm |

20/1 |

10 HP |

5 HP AC Variable |

Air cutter |

4 point PID |

50 HP |

2x4.5 |

60 - 100 |

|

XMPL -100 |

25 Ltrs |

75 mm |

20/1 |

20 HP |

7.5 HP AC Variable |

Undue water |

4 point PID |

75 HP |

2.5x7 |

80 -150 |

|

XMPL - 150 |

35 Ltrs |

90 mm |

20/1 |

25 HP |

7.5 HP AC Variable |

Undue water |

4 point PID |

100 HP |

3x9 |

120 -200 |

|

XMPL -300 |

55 Ltrs |

100 m |

20/1 |

30 HP |

10 HP AC Variable |

Undue water |

4 point PID |

140 HP |

4x10 |

170 - 300 |

|

XMPL -350 |

75 Ltrs |

110 mm |

20/1 |

30 HP |

15 HP AC Variable |

Undue water |

4 point PID |

160 HP |

4x10 |

225 - 350 |

|

XMPL -450 |

100 Ltrs |

120 mm |

20/1 |

40 HP |

20 HP AC Variable |

Undue water |

4 point PID |

200 HP |

4.5x12 |

300 - 500 |

|

XMPL -700 |

120 Ltrs |

140 mm |

20/1 |

50 HP |

25 HP AC Variable |

Undue water |

4 point PID |

260 HP |

4.5x12 |

350 - 750 |

|

XMPL -900 |

150 Ltrs |

150 mm |

20/1 |

60 HP |

30 HP AC Variable |

Undue water |

6 point PID |

300 HP |

5.5x16 |

600 - 900 |

|

XMPL -1200 |

200 Ltrs |

170 mm |

20/1 |

70 HP |

40 HP AC Variable |

Undue water |

6 point PID |

360 HP |

5.5x25 |

700 -1200 |

Applications:-

- Bio Polymer

- Non Wooven Bags

- Carry Bags

- Wooven Sack Bags

- Garbage Bags

- Tarpals

- Engineering Plastics

- PVC Cable compounding

- PVC Footwear & Soles

- Pipe Industries

- Tank Industries

- Injection Moulding

Capacities Available: 25KG/HR,50KG/HR, 100KG/HR,150KG/HR,200KG/HR, 350KG/HR,700KG/HR 1200KG/HR. We also provide Die Face Cutter separately in Air & Water on demand

FAQs of Compounding Lines For Filler And Masterbatches:

Q: What is the capacity of this compounding line?

A: The capacity of this compounding line is 1200 kg/hr.Q: Is this compounding line computerized?

A: Yes, this compounding line is computerized, making it easy to operate and monitor.Q: Is this compounding line automatic?

A: Yes, this compounding line is fully automatic, making it more efficient and less labor-intensive.Q: What material is this compounding line made of?

A: This compounding line is made of high-quality stainless steel material, ensuring durability and reliability.Q: Does this compounding line come with a warranty?

A: Yes, this compounding line comes with a warranty, ensuring that you get a top-quality product that meets all your compounding needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Call Me Free

Call Me Free